Plastic is an integral part within our day-to-day life, however we are often unaware of the dimension of problems arising alongside with it. The enormous amount of plastic produced leads to a tremendous amount of waste. This waste occurs due to the characteristic of plastics poor biodegradability. As a result plastic waste does not only ends up in landfills, but furthermore and in regards to the marine environment it also ends up in the ocean to a large extent.

A major contribution to the problem was recognized within microplastics, as due to its size (<5mm) it is easily absorbed by all organisms (e.g. fish) and thus ends up within the food chain.

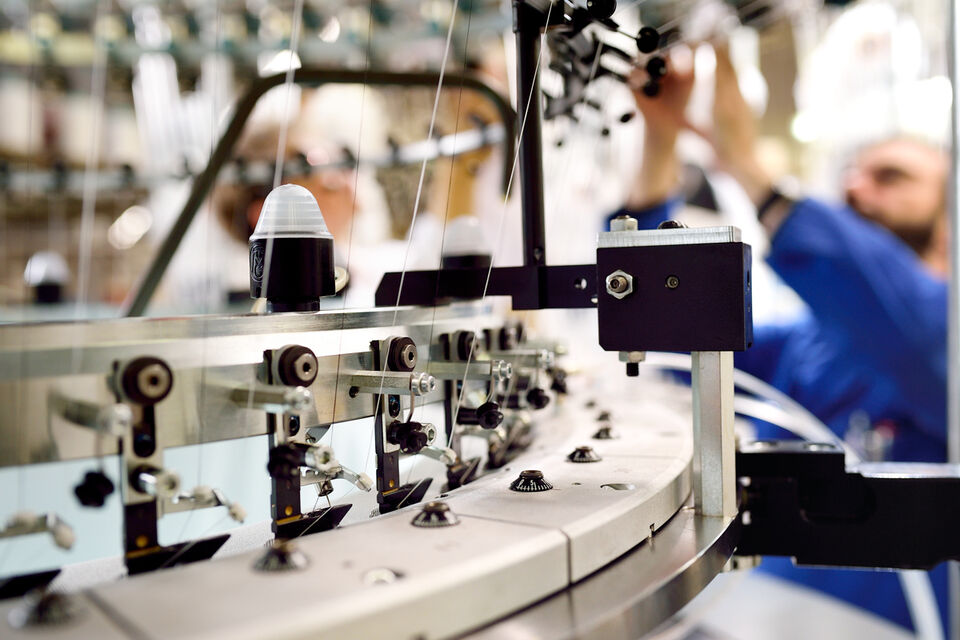

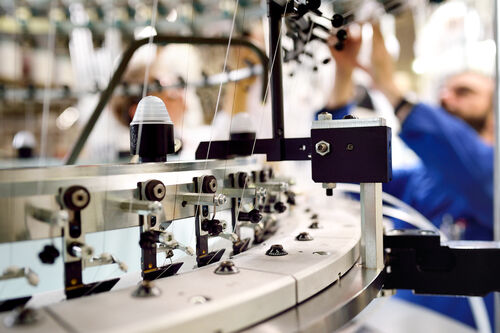

In regards to this topic, the main focus point is primarily the emergence and distribution of textile microplastics, which increasingly arise throughout manufacturing processes of synthetic textiles and the follow-up household washing procedures of those textiles.

60% -95% of all microplastic particles can be filtered out of the wastewater by sewage treatment plants. Despite these filtering processes within the sewage treatment plants, a significant proportion of microplastics remains in the clarified water (ready for e.g. consumption) and is then flushed into the environment.

The lack of knowledge about the total amount of microplastics and the corresponding entry pathways leads to a difficulty in determining the extent of the problem. In order to get one step closer and to obtain further knowledge the "TextileMission" project was launched.